- Metrologie - Labor

- Physiko-chemische Analytik

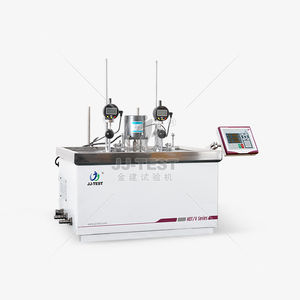

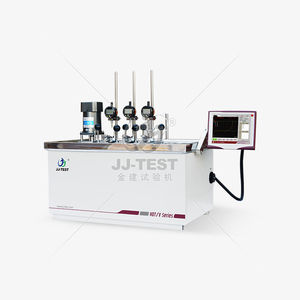

- Vicat-Prüfgerät / Wärmeformbeständigkeitstemperatur

- JJ-TEST Chengde Jinjian Testing Instrument Co.,Ltd

Vicat-Prüfgerät / Wärmeformbeständigkeitstemperatur HDT/V-3116Vicat-Punktautomatisiert

Zu meinen Favoriten hinzufügen

Zum Produktvergleich hinzufügen

Möchten Sie direkt kaufen?

Besuchen Sie unseren Shop.

Eigenschaften

- Typ

- Vicat-Punkt, Wärmeformbeständigkeitstemperatur, automatisiert

Beschreibung

Dieses Gerät ist ein Prüfgerät für nichtmetallische Werkstoffe, das nach den neuesten internationalen und nationalen Normen entwickelt und hergestellt wurde. Es wird zur Bestimmung der Wärmeformbeständigkeitstemperatur oder des Vicat-Erweichungspunkts von Polymermaterialien verwendet.

Norm

GB/T 8802

GB/T 1634

GB/T 1633

ISO 2507

ISO 75

ISO 306

ASTM D 1525

ASTM D 648

Bei diesem Gerät handelt es sich um ein technologisch fortschrittliches Gerät zur Messung der Vicat-Erweichungstemperatur und der thermischen Verformung, das 2009 von unserem Unternehmen für europäische Kunden entwickelt wurde. Seine fortschrittliche Natur umfasst die folgenden neun Aspekte:

1. Mit seiner ausgezeichneten Struktur, seinem schönen Aussehen, seiner Großzügigkeit und Einzigartigkeit ist es ein Modell für die perfekte Kombination von Industrieprodukten und Kunst.

2. Die weltweit erste Step-up automatische Hebestruktur, stabiler und zuverlässiger Betrieb, offener Testbetrieb Raum.

3. Das Probenrack wird automatisch angehoben, entladen, begrenzt, und das Probenrack wird zurückgesetzt und geladen. Der Hebevorgang wird auf einmal abgeschlossen. Diese Funktion ist auch die erste in der Welt.

4. Verschiedene Technologien, wie neue Materialien und Herstellungsverfahren sowie eine fortschrittliche Struktur, haben dazu geführt, dass der thermische Ausdehnungskoeffizient des Probengestells den Grenzwert erreicht.

5. Die Streuung der Testergebnisse der PC-Blatt-Standardprobe unter der minimalen Lastbedingung ist weniger als 0,5℃, und die technische Genauigkeit dieses Produkts ist auf dem weltweit führenden Niveau.

6. Um die Gesundheit des Bedieners zu gewährleisten und die Testumgebung nicht zu verschmutzen, ist das Gerät mit einem automatischen Rauchabzugssystem ausgestattet, und das humanisierte Design ist das Highlight des Geräts.

---

VIDEO

Weitere Produkte von JJ-TEST Chengde Jinjian Testing Instrument Co.,Ltd

Engineering plastics and products testing machines

* Die Preise verstehen sich ohne MwSt., Versandkosten und Zollgebühren. Eventuelle Zusatzkosten für Installation oder Inbetriebnahme sind nicht enthalten. Es handelt sich um unverbindliche Preisangaben, die je nach Land, Kurs der Rohstoffe und Wechselkurs schwanken können.