- Produkte

- Kataloge

- News & Trends

- Messen

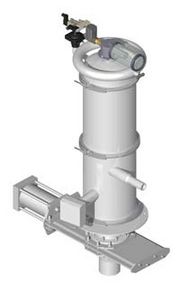

Pneumatische Förderanlage / Saug P10in verdichteter Phasediskontinuierlichfür Pulver

Zu meinen Favoriten hinzufügen

Zum Produktvergleich hinzufügen

Eigenschaften

- Typ

- Saug, in verdichteter Phase, diskontinuierlich

- Produktanwendungen

- für Pulver

Beschreibung

With the choice of various discharge valve types (powered flap and active driven butterfly valve) the P10 Venturi Loader can be used for conveying applications such as hopper loading, as well as loss-in-weight feeder refill applications, where the loader is not always emptied completely. The venturi power unit utilizes compressed air to create a vacuum convey source.

P10 Venturi Loader Design Features and Options

Constructed from DIN 1.4408 [AISI 316L] stainless steel with internal and external electropolished surface passivation, the modular construction and sanitary design, without pockets or dead spaces, allow for easy disassembly and cleaning as well as simple expansion with the optional extension modules. The P10 Venturi Loader meets 3A Dairy sanitary requirements and includes FDA accepted seals and gaskets throughout. The venturi loader also meets ATEX 2GD/1D and NEC Class 1, Div 2, Group C&D classifications.

The unit comes standard with a 115/230 VAC, 15 amp controller that is capable of handling future add-on options, such as hopper high level probes.

Designed for indoor use, the operating temperatures range between -10° C to +50° C [14° F to 122° F].

Weitere Produkte von Coperion K-Tron GmbH

Vakuum-Saugförderer

Verwandte Suchbegriffe

- Beschicker

- Waage mit separatem Anzeiger

- Dosiersystem für Feststoffe

- Dosiergerät für die Lebensmittelindustrie

- Pneumatische Förderanlage

- Zellenradschleuse

- Beschicker für Schüttgut

- Gravimetrische Dosieranlage

- Rohrweiche

- Zellenradschleuse für pneumatische Förderung

- Kontinuierlicher Beschicker

- Pneumatische Förderanlage / Pulver

- Kompakter Beschicker

- Motorisierter Beschicker

- Beschicker für Industrieanwendungen

- Pneumatische Förderanlage / in verdichteter Phase

- Rundsockel-Zellenradschleuse

- Hochpräzisions-Beschicker

- Speichertrichter

- Pneumatische Förderanlage / Saug

* Die Preise verstehen sich ohne MwSt., Versandkosten und Zollgebühren. Eventuelle Zusatzkosten für Installation oder Inbetriebnahme sind nicht enthalten. Es handelt sich um unverbindliche Preisangaben, die je nach Land, Kurs der Rohstoffe und Wechselkurs schwanken können.